IPE MFR-02 Magnesium Wheels

iPE

IPE MFR-02 Magnesium Wheels

IPE MFR-02 Magnesium Wheels

Couldn't load pickup availability

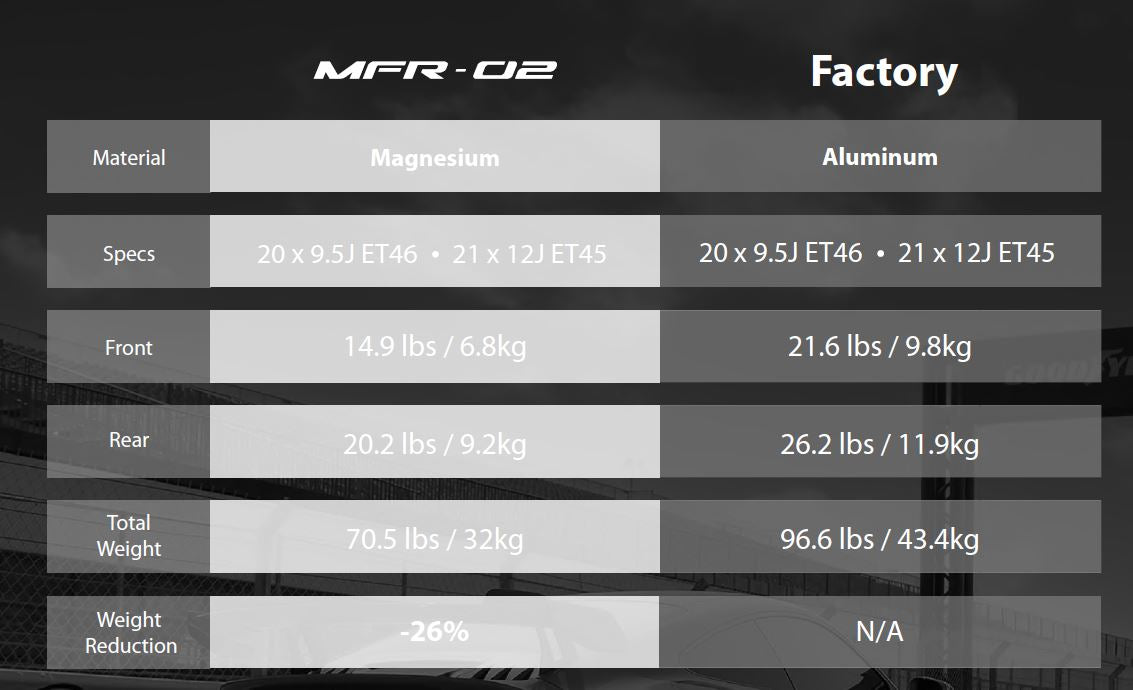

Set of 4 iPE MFR-02 Magnesium wheels for Porsche 992 GT3:

- 2x 20x9.5J+ET46 (Fronts)

- 2x 21x12.5J+ET45 (Rears)

These road legal TUV certified magnesium wheels are designed for the race track. With a 26% weight saving over the standard wheels they're the lightest on the market.

Lighter yet Stronger

The craftsmanship of MFR-02 is incredible without sacrificing strength and safety. It weights in front at just 14.9 lbs / 6.8kg, rear at 20.2 lbs / 9.2kg. It sets up an exciting chapter for iPE.

MFR-02 also have proven by the world’s most respected and strictest certification – TÜV Nord. That guarantees quality and safety for the consumers, including SAE certification.

Forged Magnesium

Magnesium is the lightest structural metal available by far and it shows lower density, higher specific strength and exceptional machinability.

- 30% LIGHTER THAN FORGED ALUMINUM BY VOLUME

- 12% SPECIFIC STRENGTH* STRONGER THAN ALUMINUM

- HIGH DAMPING CAPACITY

- ECO-FRIENDLY AND RECYCLABLE

Innovation

Magnesium wheels are usually applied to race cars, and it can reduce unsprung mass, shorter braking distance, faster acceleration, and improve overall performance.

- UNSPRUNG MASS DEDUCTION

- SHOCK ABSORPTION FOR BETTER HANDLING

- HIGH THERMAL CONDUCTIVITY TO PROLONGING LIFE OF BRAKE SYSTEM

- BETTER FUEL EFFICIENCY

World-Leading Manufacturing Process

- 10,000-TONS FORGING PRESS

- HOT FLOW FORMING

- HEAT TREATMENT

- CNC TURNING

- CNC MILLING

- POLISH & GRINDING

- MICRO-ARC OXIDATION(MAO)

- ELECTRO-DEPOSITION COATING (ED)

Certified Strength

Every process for the MFR-02 is critical in order to produce the highest standard quality wheels. Under strong and safety condition, iPE provides ideal products for the consumers.

- RADIAL FATIGUE TESTS

- ROTARY FATIGUE TESTS

- IMPACT FATIGUE TESTS

OE Cap Ready for:

- PORSCHE 992 GT3